Handweaving looms, the likes of which have been around for millennia, and Reddit, the geeky male-dominated online discussion forum, came together in the origin of directional unisex slow denim brand Story mfg in early 2014. The first pairs of jeans that Katy Katazome, former denim editor at WGSN and her partner, tech-nut Bobbin Threadbare, (appropriately named after a 1990s Lucasfilm adventure game character) sold were to members of a Reddit discussion thread on denim – shortly before they were picked up by LN-CC. In fact, Threadbare, a longtime member of the denim thread, consulted with members over the shape of the pockets in their first pair of jeans, and shared images during research trips to India in search of natural indigo-dyed cotton and handwoven denim.

A mutually beneficent relationship between fast and slow technologies has defined the brand since its inception: modern air travel whizzed the pair over to India in January 2014, but when they arrived it was through relentless word-of-mouth investigation and multiple taxi journeys that they eventually arrived at the natural dyeing micromill The Colours of Nature, from whom they bought rolls of deadstock denim to make their first pair of jeans. Likewise, during our interview, Katazome receives messages via LINE (a messaging app popular in Asia) from the Thai village matriarch responsible for communications between a group of women who produce denim for the brand. “Most of our handweaving is done in Thailand in a set-up similar to how Harris Tweed is made,” says Katazome, “retired ladies who were farmers and who grow the cotton and grow the indigo in their garden and handweave it. The women we work with are a community like a knitting circle who are trying to train the younger generations, we found them through a huge journey around Thailand.” But the weaving has to work with the farming calendar: “The last thing we want is to stress the women out who work for us, so I closed our order window really early to give them plenty of time to weave, but she messaged me saying they wouldn’t be able to start for a month and a half because the rice harvest was late, and that’s just how it is!” “We’re slaves to the weather”, said Threadbare (real name, Saeed Al-Rubeyi), “it varies the colour so much and what we can do.”

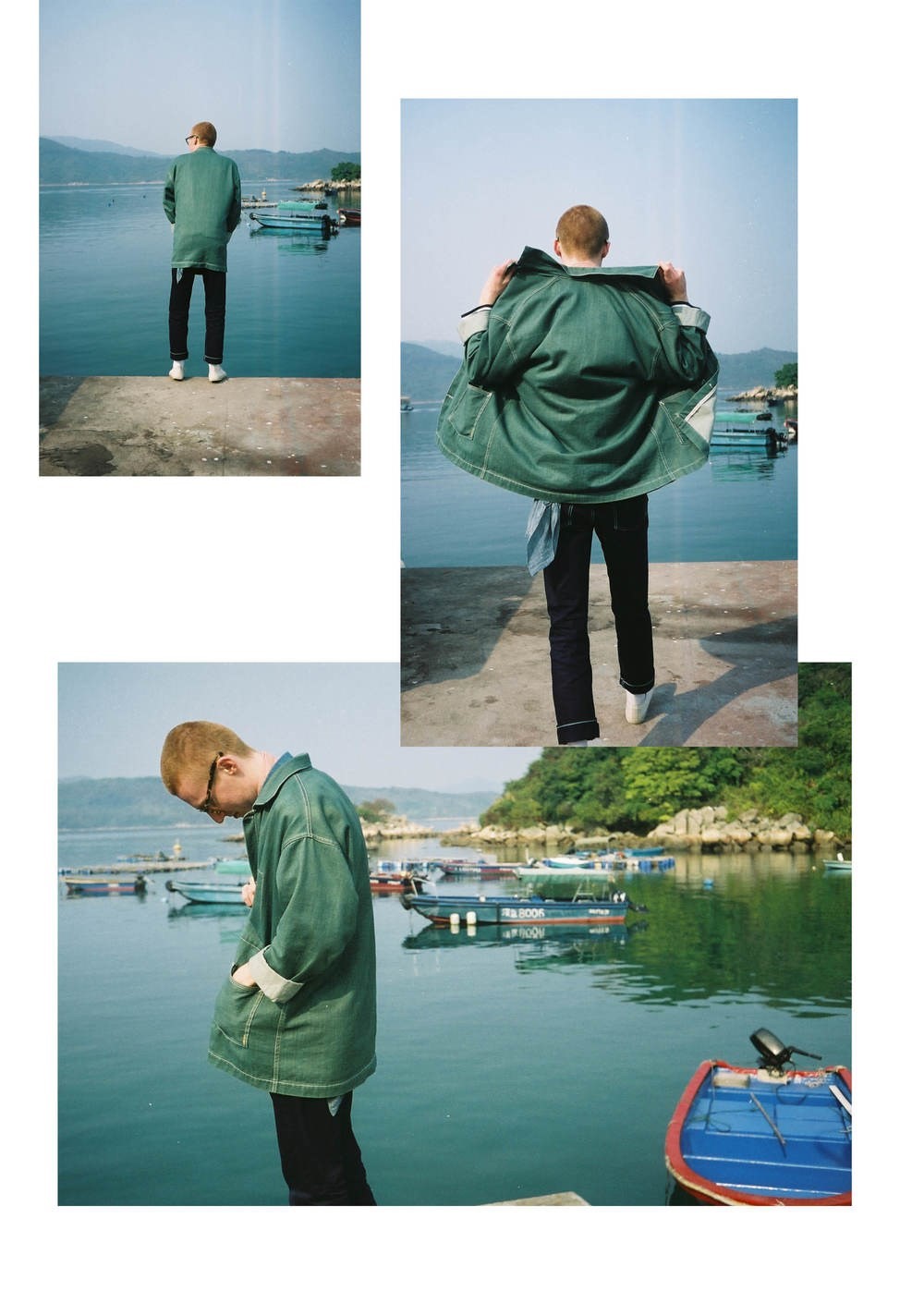

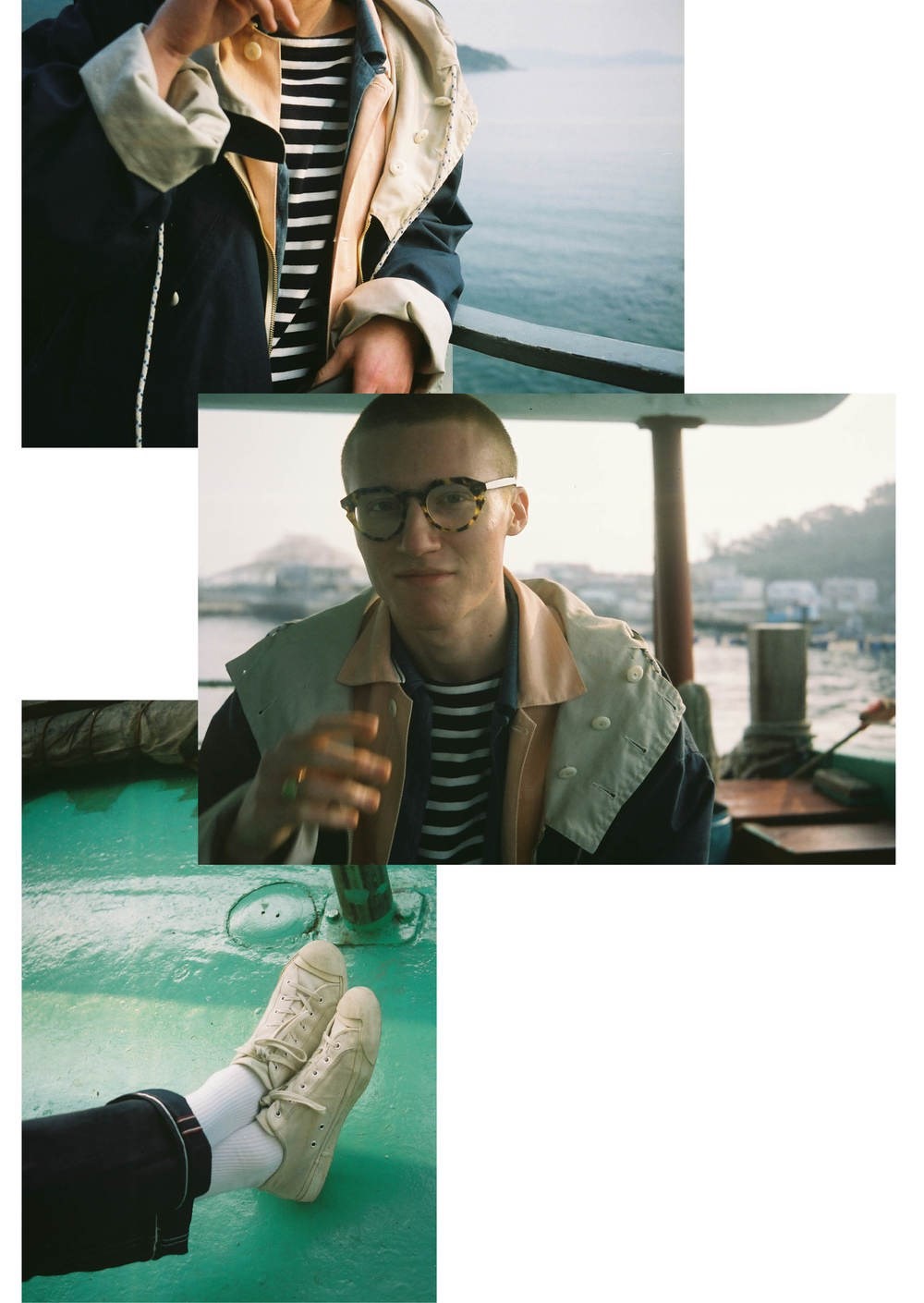

The mix of fast and slow defines Story mfg’s aesthetic too. “Sometimes the types of fabric that we use, slow organic types, is what people put in really hippy stuff or super over-simple styles and it gets lost. We are trying to incorporate it in to a much more directional style, it has to be directional,” said Threadbare. Indeed, while Story mfg’s making processes might be old fashioned and slow, the styling of their current collection is targeted at an on-trend, youthful audience, its imagery depicting a group of bored teenagers in embroidered bomber jackets and cropped, wide-cut denim and T-shirts messing around a river, throwing stones and shooting the shit. Current season jackets include one featuring an embroidery map of the Brexit vote on the back, reflecting the re-invigorated enthusiasm for politics among generation X, who are their best customers. “We didn’t expect it, but it’s the 16-21 year olds who are buying our stuff the most,” commented Threadbare.

The brand found its early champion in the figure of LN-CC founder John Skelton, when some pieces they’d made with batik caught his eye – he subsequently put in their first big order. “It was for £11,000 which was a lot to us then,” said Threadbare. “We’d been to India and been doing some more complicated things with batik, and of course they were then the thing that LN-CC wanted, so we had to fly to India the next weekend with our jackets in our suitcases, and batik them then fly back again,” continued Katazome. “We were like ‘right, we’re in a store now, we need to be serious!’ Being in LN-CC, that gave us the credibility and because they were pushing the ‘conscious’ idea, other stores latched on. John Skelton who was there has helped a lot with advice that we’ve needed, and contacts.”

After pre-selling a few jeans to enthusiasts via Reddit in 2014, the company – which has been entirely self-funded, with each collection funding the cloth for the next while both Katazome and Threadbare continue to work other jobs – has grown apace. “For next season we’ve got 18 stockists and we’re going to be turning over 100K this year, and next year is our profit year. In our first year we had 9K, then we had about 40K, and this year we’ll have over 100K,” said Threadbare. Such extraordinary growth is forcing the pair to become slightly more organised in their manufacturing – orders are too big to pack into their suitcases. Katazome and Threadbare put in a lot of time travelling to hunt out small mills working with natural dyes and doing handweaving to work with. I asked then about their interest in ‘Made in Britain’ – for some ‘slow’ brands, a holy grail – as they have had some garments made up in the UK. “A lot of the manufacturers we’ve met in the UK – with the exception of Blackhorse Lane Atelier – have mentally abandoned their own business; there’s no language barrier, and they’re only a few hours up the M1, but they don’t reply to emails, it’s very stressful and the quality has not been as good as we’re getting with the traditional, family-run hand weavers and makers in India and Thailand,” explained Katazome. “For all that we want to close the circuit, the implication that the quality could not be as good elsewhere is xenophobic,” Threadbare continued.

Politics is woven into the fabric of the company: the women who work in the mills they work with in India have shares in the company and manage their own schedules; both Katazome and Threadbare are vegan, as are all of their products; and kindness is a principle they have placed at the heart of how they deal with the people who make for them – but they don't shout about that, because they worry it will give the wrong impression of their styling and the aesthetic direction of their brand. For Story mfg, as ever, the future involves a mix of fast and slow: “we want a blended future of the best of the handmade, natural processes and with new tech-fabrics,” said Threadbare – a plan their fanbase are sure to love.